Get off to an efficient start with the REPRECT TOPSTEPS starter pack -

Your solution for industrial staircase production

In times of rising costs and growing demands for efficiency and flexibility, solutions are needed that are not only technically convincing, but also make economic sense. With the new REPRECT TOPSTEPS starter pack we offer you exactly that:

One Cost-effective entry into industrial staircase production from € 100,000depending on the initial situation, up to 25 – 50 % of manufacturing costs can save – even from batch size 1.

Why a starter pack?

The entry into industrial production is often associated with high investments. Our starter package is aimed at companies, quickly, efficiently and with manageable effort. want to enter industrial production. It combines a Intelligent software solution with tried and tested equipment and thus enables a smooth start to production.

What is included in the package?

- Access to our specialised software (PCS)

for the creation of:- Planning data (formwork plan, reinforcement plan)

- Machines and setting data

- Plan for formwork construction

- The equipment required for entry into industrial production

- Formwork for stairs with and without landings

- Step cores

- Manual reinforcement template

- Welding template for head / base elements

- Parking and turning device

- Template for end formwork

What can be produced with the starter pack?

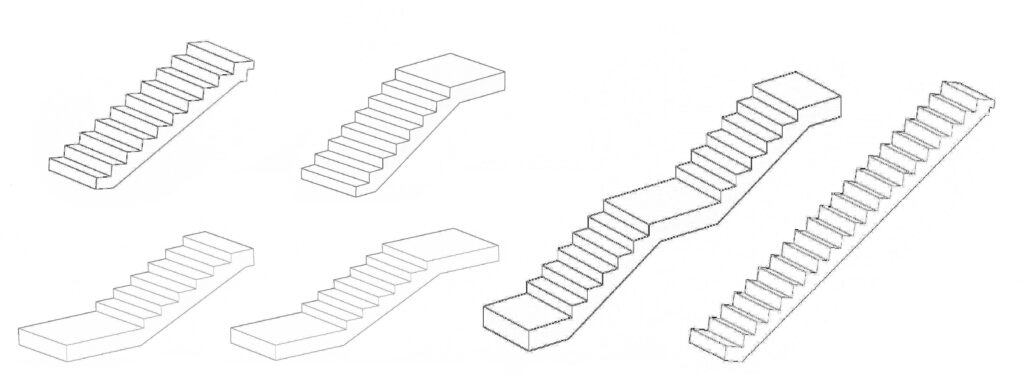

- Straight staircases in a wide variety of designs:

- Straight stairs

- Landing stairs

- Stairs with landing above & below („Z” stairs)

- Stairs with intermediate landing

- The starter pack is intended for the following production quantities:

- Daily production

- Ø 1.5 Stairs

- Annual production

- 300 pieces+

- Double installation

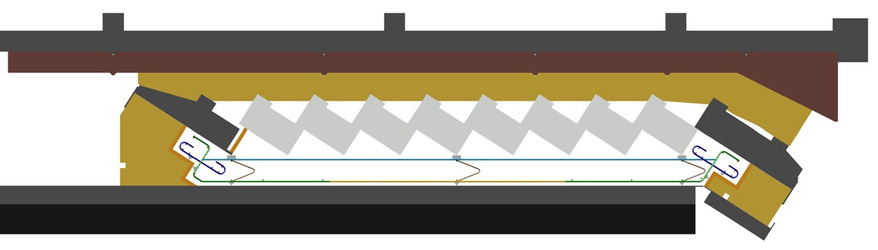

- With the REPRECT-TOPSTEPS staircase production system, it is possible to produce 2 staircases with different riser ratios in one mould at the same time, thus increasing the efficiency of the equipment.

- Depending on the geometry of the stairs to be manufactured, the double installation makes it possible to produce an average of 1.5 stairs per working day.

- Daily production

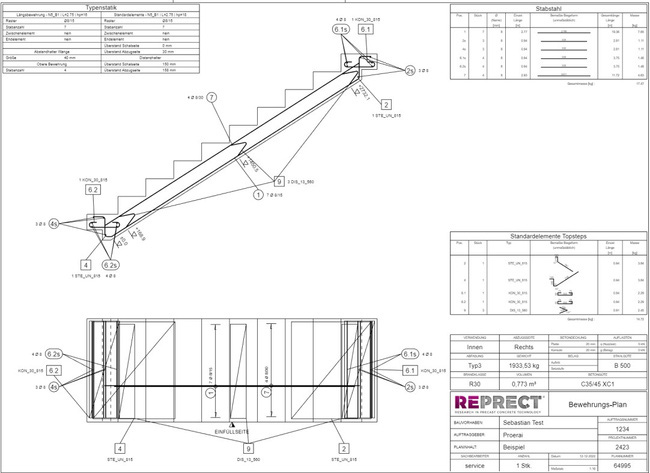

REPRECT – TOPSTEPS special software

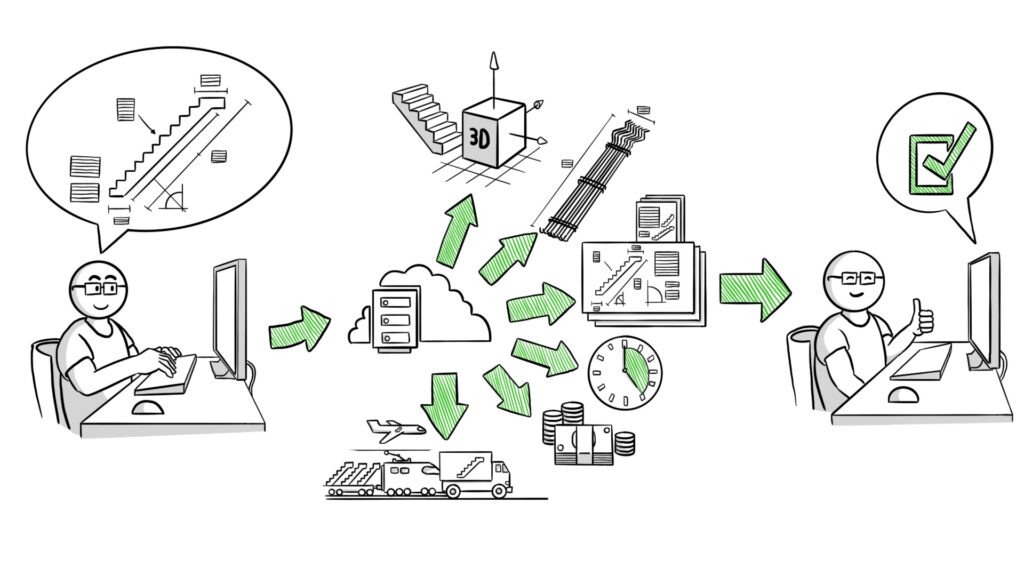

With our specialised software (PCS), you can automate the entire production process for prefabricated staircases.

The software generates all production data fully automatically by simply entering the staircase parameters – anytime and anywhere.

After entering the staircase parameters, you will receive

- Shuttering plan

- Reinforcement plan

- 2D & 3D data of the staircase and formwork

- Production data (machine data)

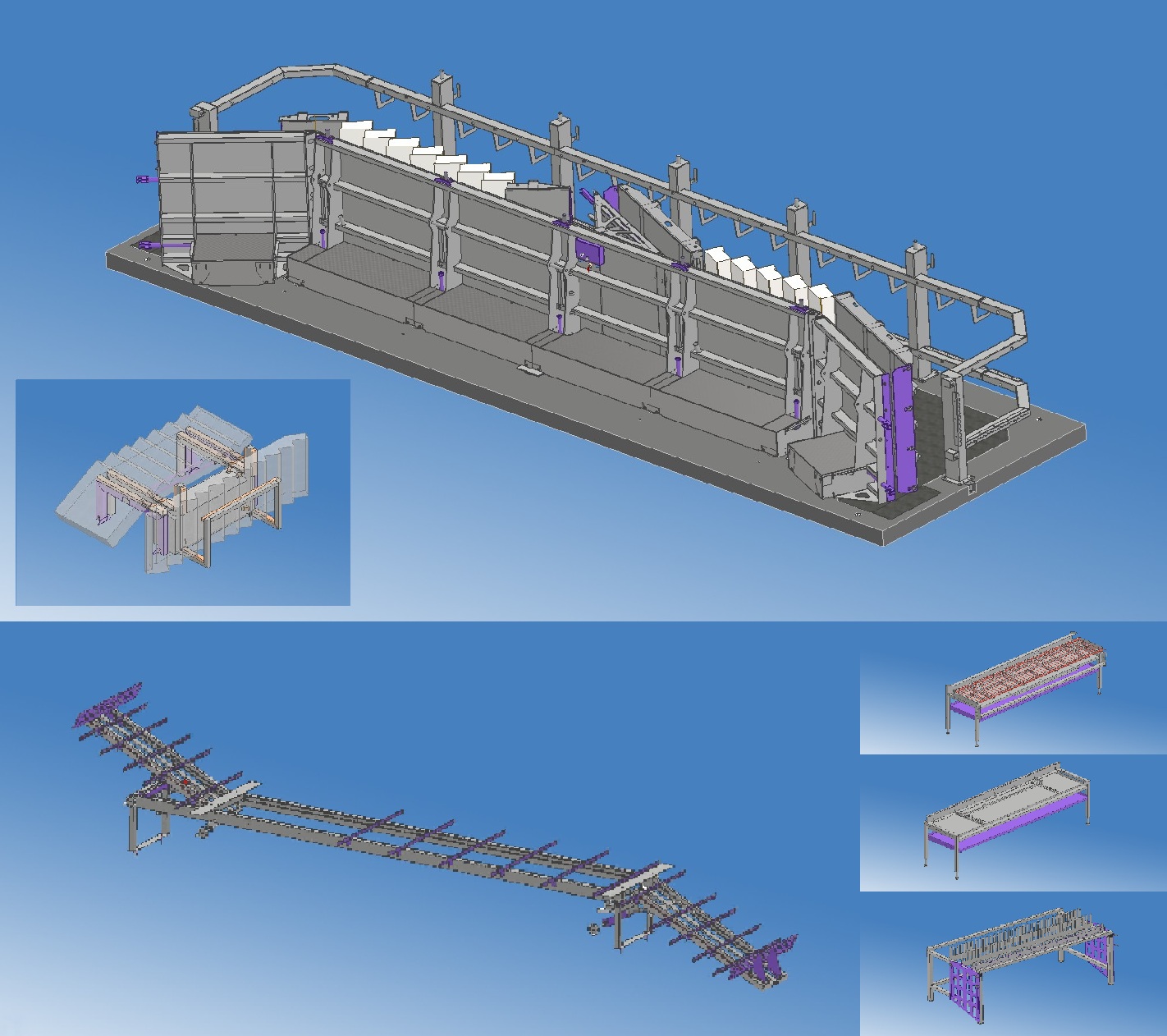

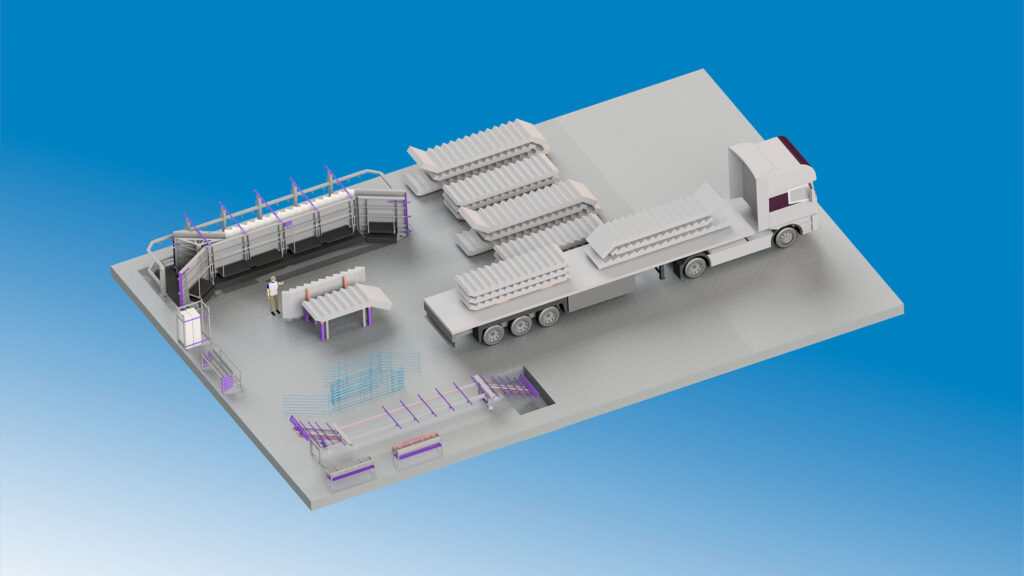

The starter pack – equipment

More details on the equipment included:

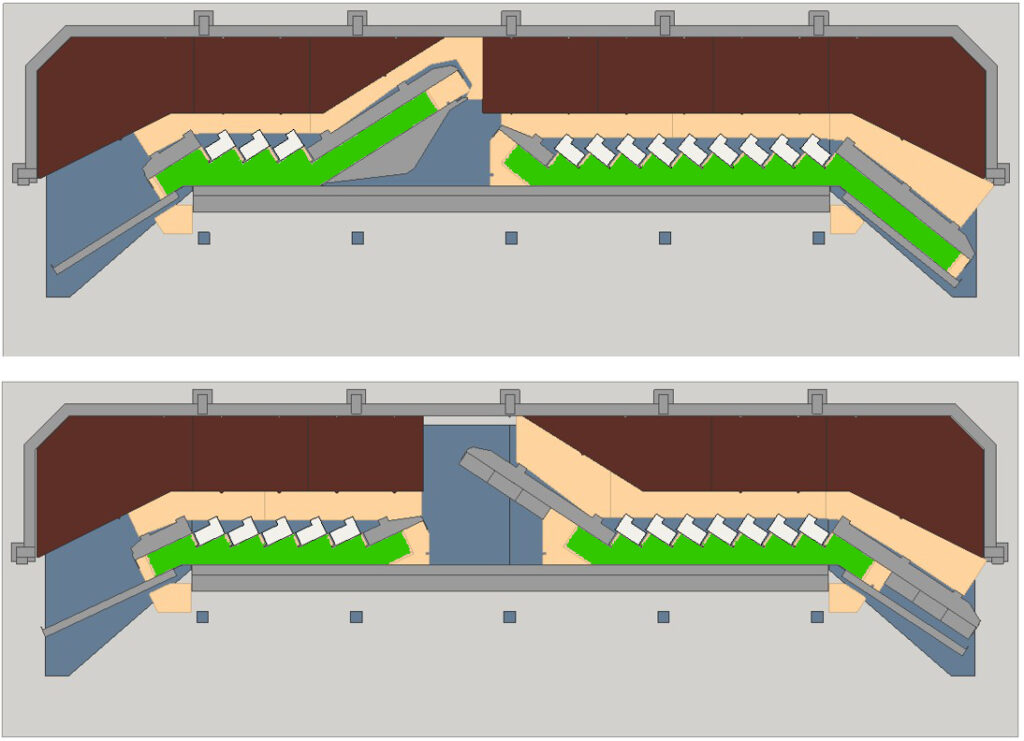

- Formwork for stairs with and without landings

- for landing lengths up to 165cm and stair widths up to 145cm

(Additional dimensions are possible at an extra charge)

- for landing lengths up to 165cm and stair widths up to 145cm

- Step cores

- 18 individual step cores for interchangeable risers

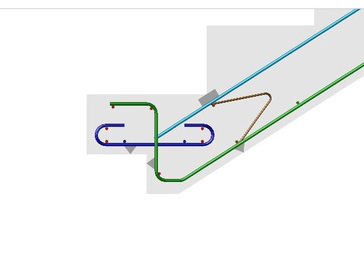

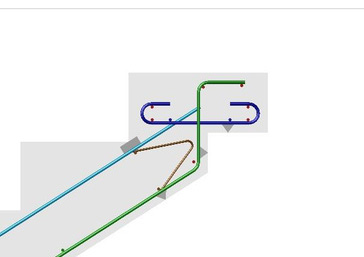

- Manual reinforcement template

- Manually adjustable template for the production of precise reinforcement cages according to the REPRECT – TOPSTEPS type statics, as well as reinforcement cages in conventional design

- The template is set using the data determined by the special software.

- Welding template for head / base elements

- Template for the prefabrication of header and footer elements for subsequent processing in the manual reinforcement template

- Parking and turning device

- Device for parking, turning, intermediate storage and as a workstation for reworking the finished stairs

- Template for end formwork

- Device for quick production of the timber end formwork with predefined position points for the timber boards – no measuring required

Expert knowledge included!

Benefit from our expertise: in Expert interviews our experienced consultants and engineers share valuable tips, best practices and insights into industrial staircase manufacturing.

Conclusion: The smart entry into staircase production

The REPRECT TOPSTEPS starter pack is more than just a product – it is „the entry into” a Integrated production conceptthat paves your way into industrial production. Whether as an entry-level solution or to expand existing capacities: With REPRECT TOPSTEPS, you can rely on a future-proof solution.