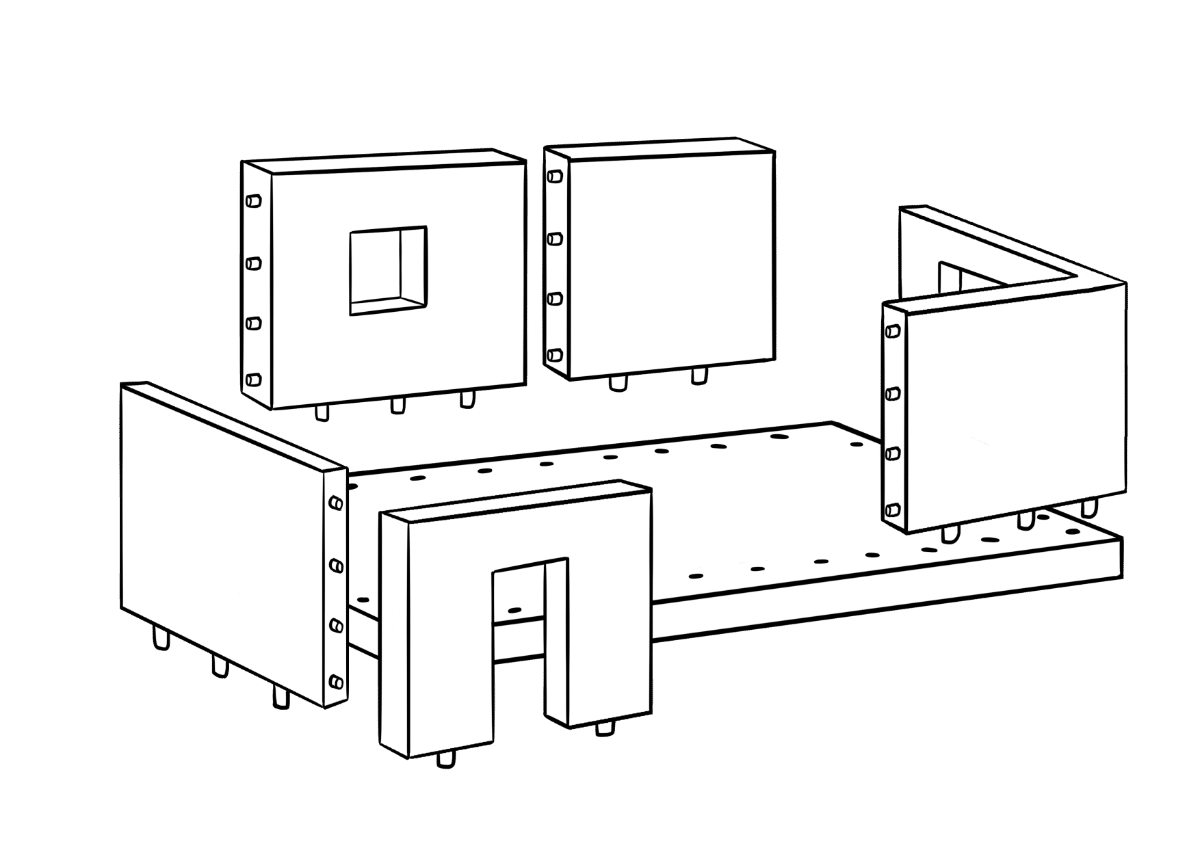

The vision: to erect a building using autonomous - or at least partly autonomous - assembly of site-ready elements - or, to put it simply:a construction site free of people and materials- in contrast to today's cluttered construction sites.

The objective:manufacturing components in a plant by implementing three key measures:

- Evolution of precast construction over the entire life cycle,

- Digitalisation of the whole life cycle, and

- Disruptive technologies

The construction site of the future is to be largely standardised and automated, similar to many other industries today.

Essentially, there are 3 areas which form the basis of the idea for the industrialisation of building construction.

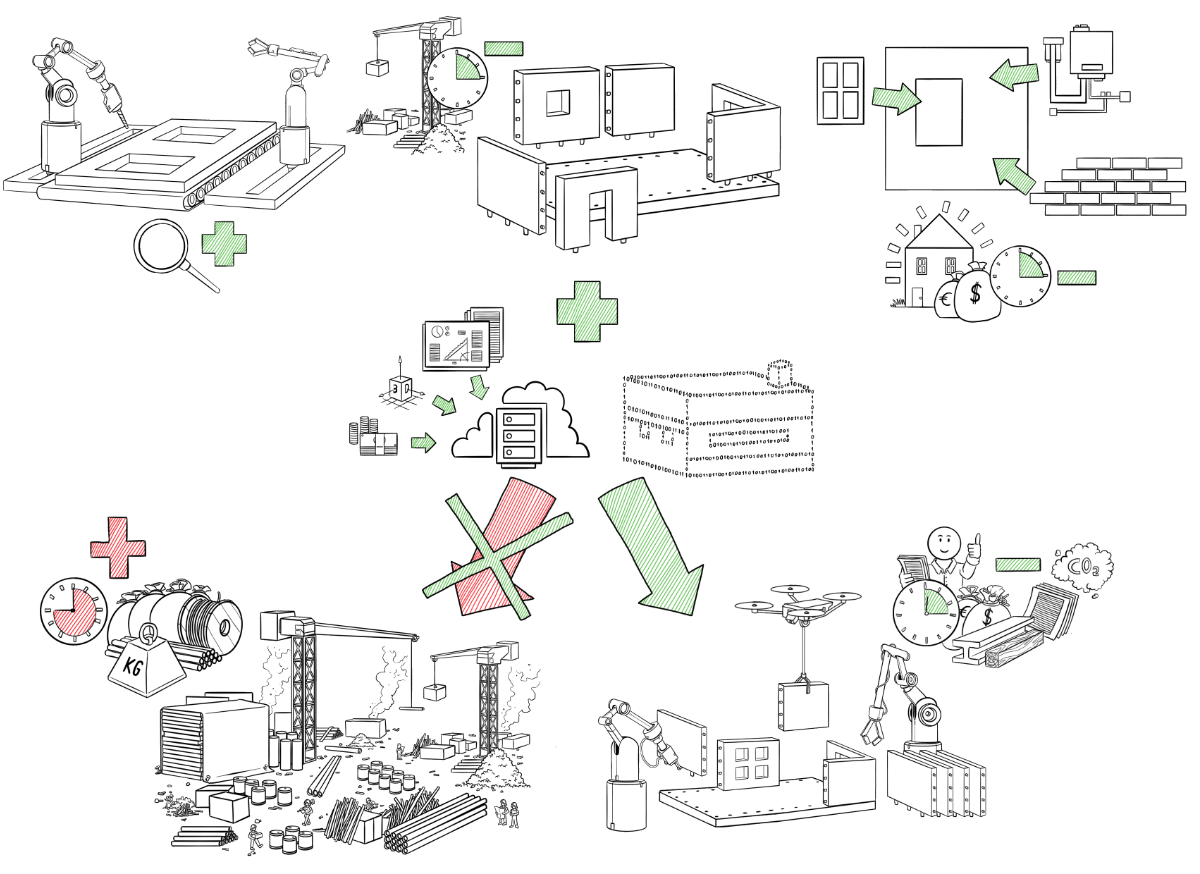

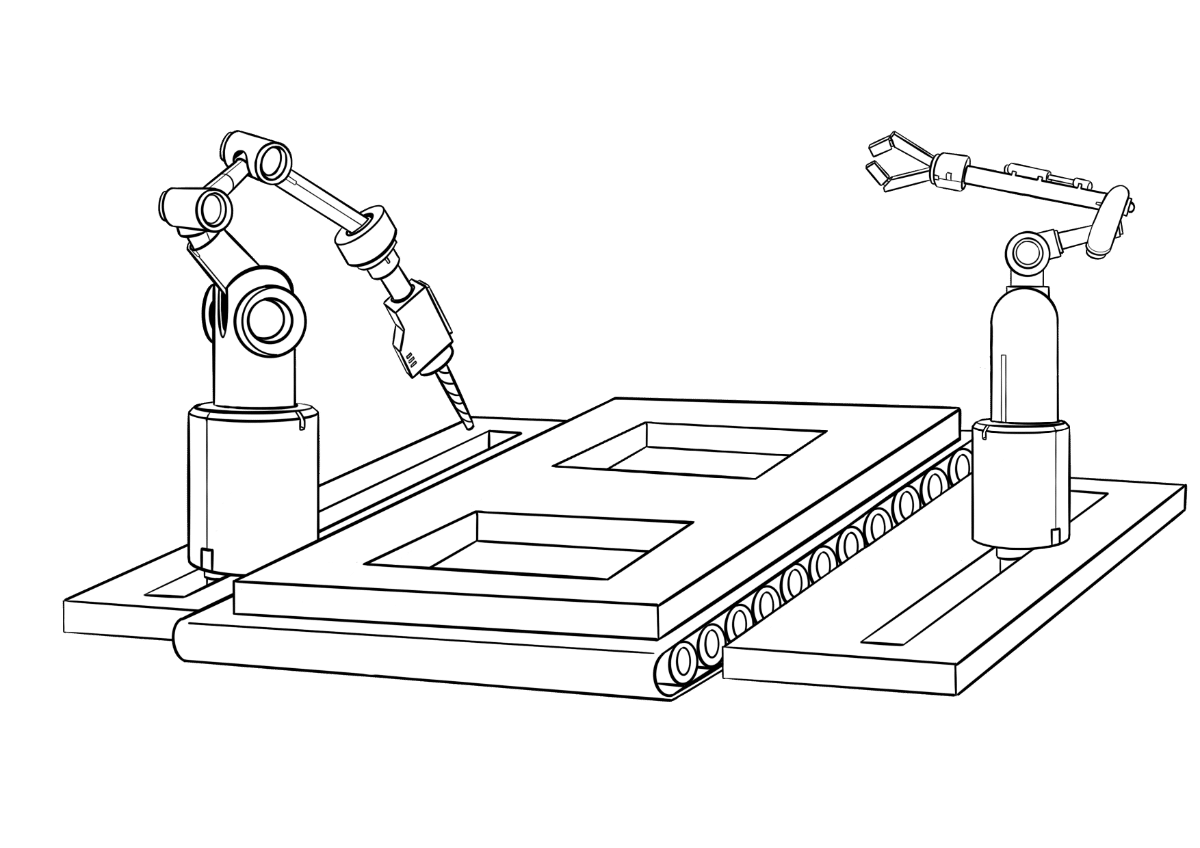

1. Industrial manufacturing systems for precast concrete parts that allow highly automated production through robot-supported machining and do not require qualified specialists - taking the automotive industry as an example (see figure 1).

(a): robot-assisted industrial manufacturing systems for precast concrete parts

(b): automotive industry shows how it is done

Figure 1: Robot-supported industrial manufacturing systems for precast concrete parts

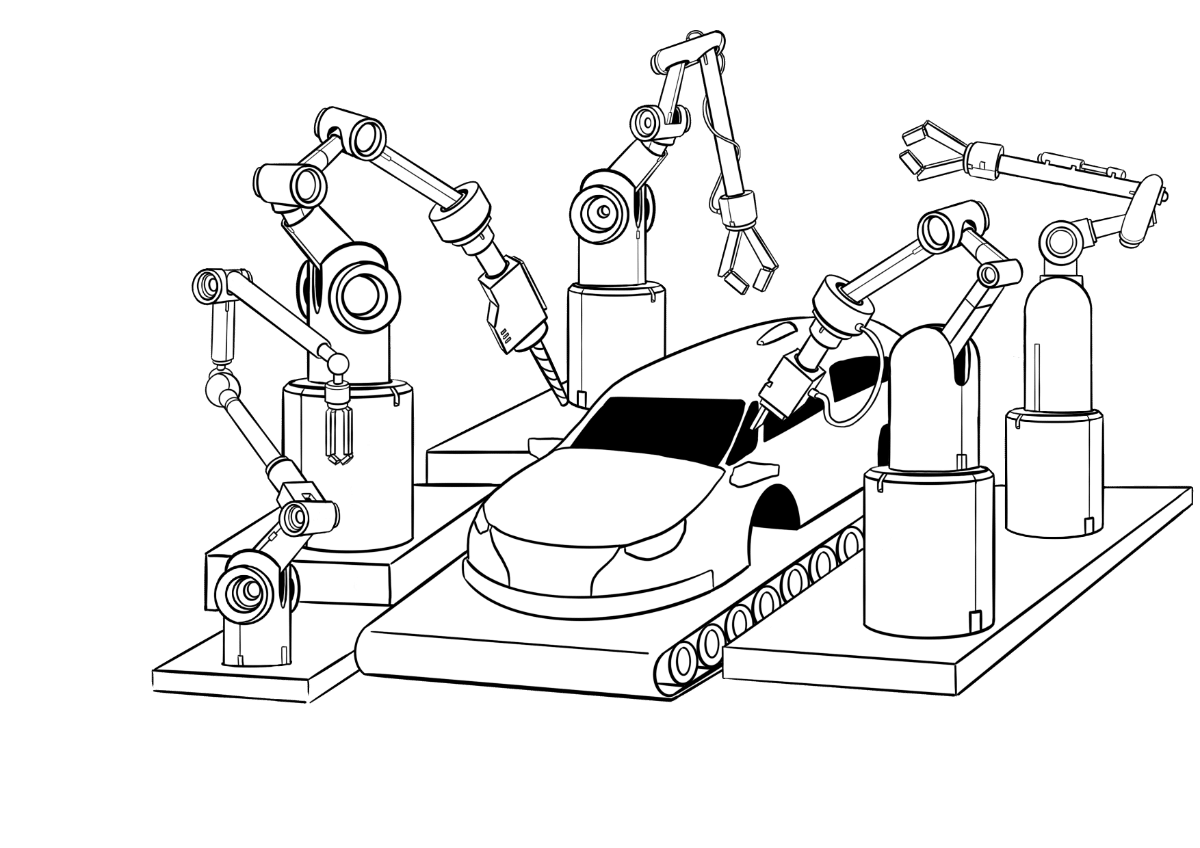

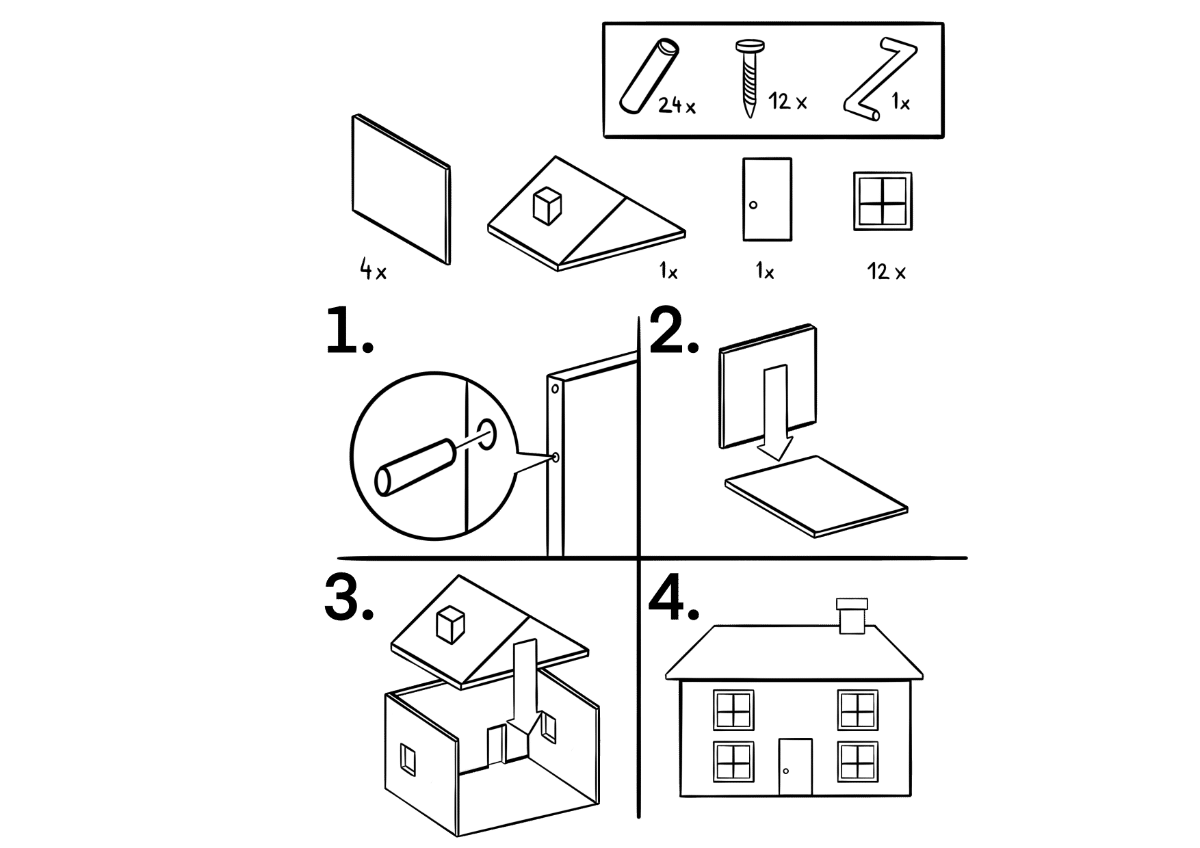

2. New technology for the assembly (= assembly system) of precast concrete parts that allows simple assembly on the construction site thanks to industrial machining and does not require any special skills on the part of the personnel - the IKEA model (see figure 1).

(a): new technology for assembly

(b): IKEA model

Figure 2: new technology for assembly

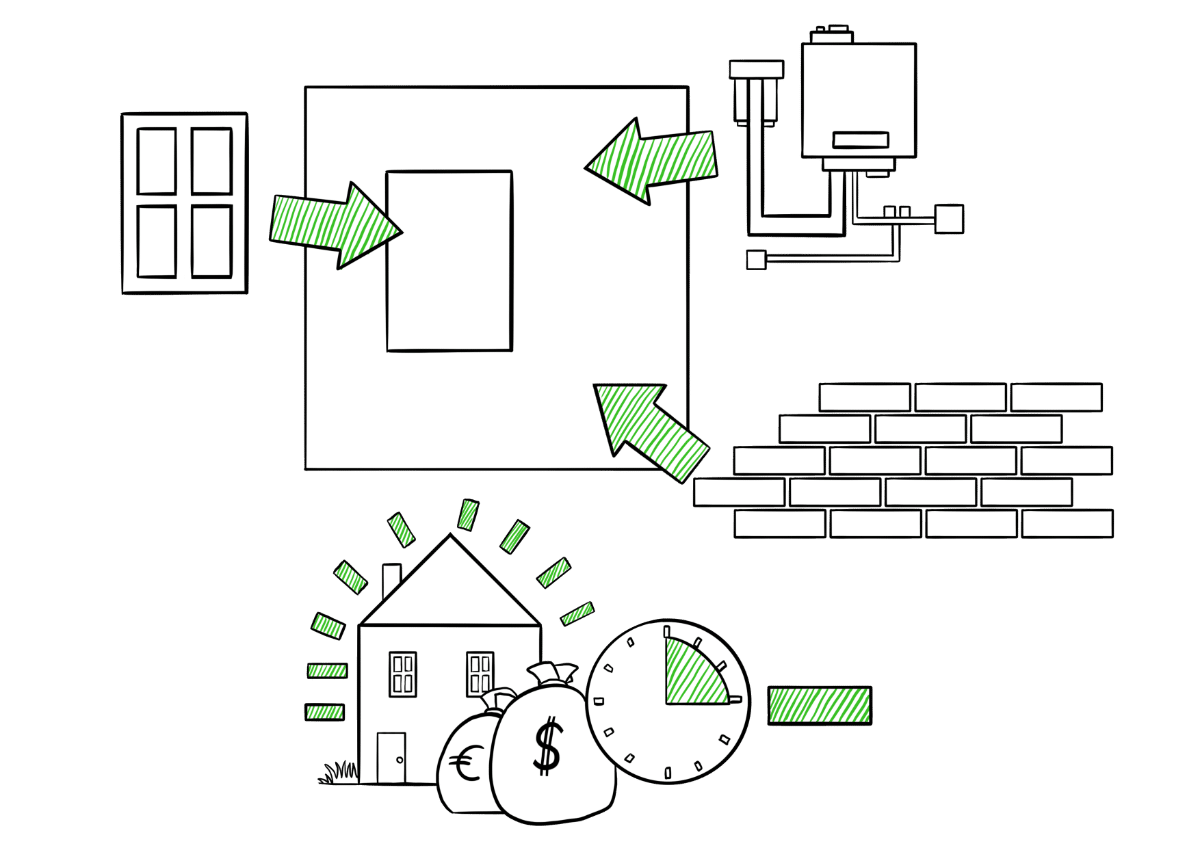

3. Maximum integration of subsystems with the aim of achieving (a) reduction of interfaces and potential sources of error, (b) shortening of construction times, (c) increase in quality and (d) increase in the degree of completion

Figure 3: Integration of subsystems

Together, these three areas are intended to simplify (building) construction in such a way that significantly fewer personnel - and in particular qualified specialists - and materials are required on the construction site.

Benefits of InHo:

- Increasing the dimensional accuracy and quality of each component and as a result the entire structure

- Higher value added and level of completion

- Conservation of resources and reduction in emissions

- 100% quality control

- Significant reduction in construction time

- Digitalisation of each component and the entire structure

Our innovative approach to the overall standpoint - integrating the different trades (integration of subsystems) across the entire supply chain and the entire life cycle (from planning to execution to dismantling / recycling) – complies with our goal of implementing disruptive innovations with the aim of marketing the know-how through licenses.